Contact

E-mail:

Phone

Add:

Jianghe River Industrial Zone, Jing County, Hengshui City, Hebei Province

Mining Screen Set Products

- 产品描述

-

Mining Screen Set Products

In the world of mining, efficiency and effectiveness are crucial for maximizing output and ensuring safety. One of the essential components in this process is the mining screen set products. These products play a vital role in separating materials, whether it be ores, aggregates, or other minerals. This article will explore the various types of mining screen set products, their applications, and the factors to consider when selecting the right screens for specific mining operations.

Types of Mining Screen Set Products

Mining screen set products come in various forms, each designed for specific tasks within the mining process. The most common types include vibrating screens, trommel screens, and static screens.

Vibrating screens are perhaps the most widely used in the mining industry. They utilize a series of screens that vibrate to separate materials based on size. The vibration causes the materials to move across the screen surface, allowing smaller particles to pass through while larger ones are retained. This type of screen is highly effective for separating materials in both wet and dry conditions and is commonly used in mineral processing plants.

Trommel screens, on the other hand, are cylindrical screens that rotate to separate materials. As the drum rotates, materials are lifted and dropped, allowing smaller particles to pass through the screen while larger ones are pushed to the end. Trommel screens are particularly effective for processing materials that contain a high level of moisture, such as soil or clay, making them ideal for applications in gold and diamond mining.

Static screens are another type of mining screen set product. Unlike vibrating and trommel screens, static screens do not have moving parts. They rely on gravity and the natural flow of materials to separate particles based on size. While static screens are less efficient than their vibrating and trommel counterparts, they are often used in applications where maintenance is a concern or where the separation process is less demanding.

Applications of Mining Screen Set Products

Mining screen set products are used in various stages of the mining process. They are essential for the initial separation of materials, helping to remove unwanted particles and prepare the ore for further processing. This is particularly important in mineral processing, where the quality of the final product depends on the effectiveness of the screening process.

In addition to mineral processing, mining screens are also used in aggregate production. The construction industry relies heavily on crushed stone, sand, and gravel, all of which require efficient screening to ensure the right particle size for various applications. Mining screen set products help producers meet stringent specifications for construction materials, ensuring that the final products are suitable for use in roads, buildings, and other infrastructure projects.

Furthermore, mining screens are utilized in recycling operations. As the world becomes more focused on sustainability, the recycling of materials such as metals, plastics, and glass has gained importance. Mining screen set products aid in the efficient separation of recyclable materials, making it easier to process and reuse these materials in new products.

Factors to Consider When Selecting Mining Screen Set Products

When choosing mining screen set products, several factors should be considered to ensure optimal performance and efficiency. The first factor is the type of material being processed. Different materials have varying properties, such as size, weight, and moisture content, which can affect the screening process. Understanding the characteristics of the material will help in selecting the appropriate screen type and design.

Another important factor is the desired separation size. Different applications require different particle sizes, and selecting a screen that can effectively achieve the desired separation is crucial. This may involve choosing screens with varying mesh sizes or configurations to ensure the best results.

The operating environment is also a key consideration. Mining operations can be harsh, with exposure to dust, moisture, and extreme temperatures. Choosing screens that are durable and can withstand these conditions is essential for minimizing downtime and maintenance costs.

Finally, it is important to consider the overall cost of the mining screen set products. While it may be tempting to choose the cheapest option available, it is essential to evaluate the long-term value of the screens. Investing in high-quality screens that are efficient and durable can lead to significant cost savings over time.

Conclusion

Mining screen set products are an integral part of the mining process, playing a crucial role in the efficient separation of materials. With various types available, including vibrating screens, trommel screens, and static screens, there are options to suit a wide range of applications. By considering factors such as material characteristics, desired separation size, operating environment, and overall cost, mining operations can select the right screens to maximize productivity and ensure the quality of their final products. As the mining industry continues to evolve, the importance of effective screening solutions will remain paramount in achieving operational success.

Key words:

Related Products

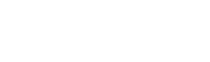

Flotation Machine Rotor Stator